Best Practices for AI-Driven Competitor Supply Chain Analysis

In today's hyper-competitive landscape, understanding rival supply chain operations has become mission-critical for sustained success. AI-driven competitor supply chain analysis transforms raw data into actionable intelligence, empowering leaders to anticipate market shifts and optimize operations proactively. By leveraging machine learning and predictive analytics, businesses gain real-time visibility into competitors' logistics, inventory management, and supplier relationships—enabling smarter strategic decisions that drive efficiency and innovation.

Key AI technologies revolutionizing supply chain analysis include:

- 📊 Demand Forecasting: Algorithms analyze historical patterns to predict market needs, optimizing inventory allocation

- 🤖 Intelligent Warehouse Systems: AI-powered robotics streamline picking/packing processes while reducing errors

- 🛣️ Route Optimization: Real-time analysis of traffic, weather, and fuel costs creates efficient delivery corridors

flowchart LR

A[Competitor Data] --> B[AI Processing]

B --> C[Predictive Insights]

C --> D[Strategic Decisions]

Identifying Key Competitors and Their Supply Chain Strategies

Pinpointing the right competitors to monitor is foundational to effective supply chain intelligence. Not all market players impact your operations equally—focus on those whose logistics decisions directly affect your market position or resource availability. AI tools can rapidly scan industry ecosystems to identify primary threats based on market share overlap, customer base similarities, and geographic presence.

Practical steps for strategic competitor mapping:

-

Create competitor matrix:

- Direct competitors (similar products/services)

- Indirect competitors (alternative solutions)

- Emerging disruptors (new market entrants)

-

Analyze supply chain models:

- Supplier diversification patterns

- Inventory turnover benchmarks

- Sustainability certifications

- Logistics partnership networks

-

Leverage AI pattern detection: Monitor for strategic indicators like:

- Sudden shipping route changes

- Unusual raw material purchases

- Warehouse expansion permits

💡 Pro Tip: Set automated alerts for competitor SEC filings mentioning "logistics" or "supply chain"—these often signal strategic shifts

Leveraging AI for Real-Time Supply Chain Monitoring

Continuous competitor surveillance provides the agility needed in volatile markets. AI-powered monitoring delivers instant alerts about rival activities that could impact your supply chain strategy—from product launches to partnership announcements. Real-time intelligence allows you to adjust procurement, production, and distribution before market conditions shift.

Critical Monitoring Areas with Real-World Examples

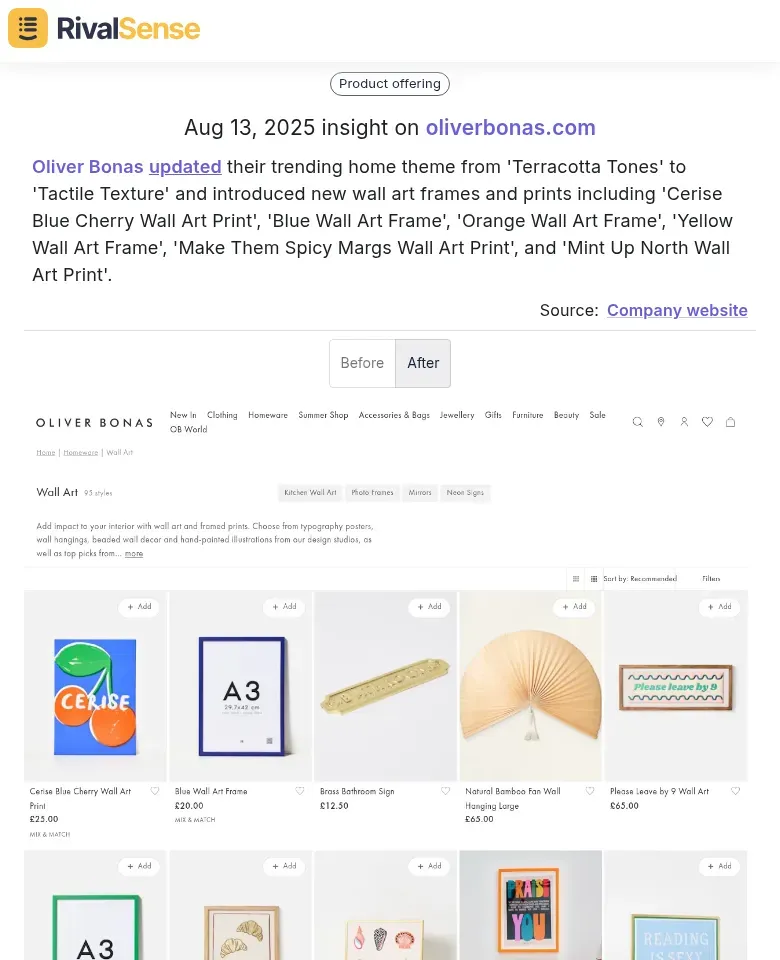

Product Line Changes

Oliver Bonas updated their home theme and introduced new wall art collections

Strategic Value: Tracking product refreshes helps anticipate material demand changes. If competitors shift product lines (e.g., from terracotta to textured home goods), you can preemptively secure relevant raw materials.

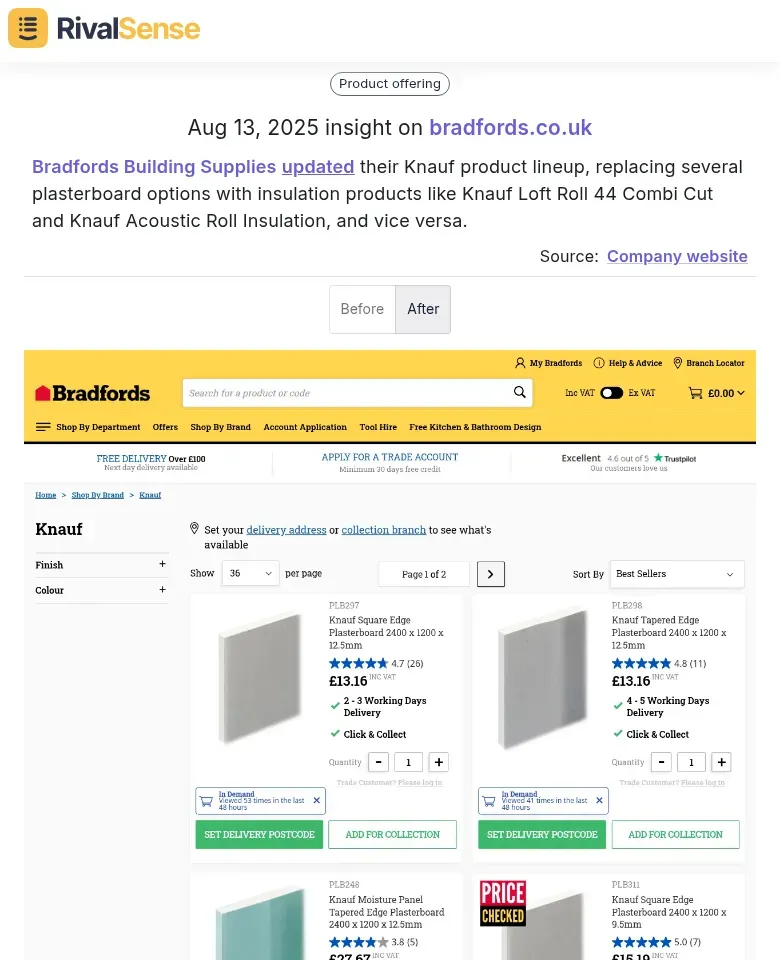

Supplier Portfolio Shifts

Bradfords replaced plasterboard options with Knauf insulation products

Strategic Value: Material substitutions signal supply chain vulnerabilities. When competitors switch core components, investigate whether it's driven by cost, scarcity, or regulations—then adjust your sourcing strategy accordingly.

Technology Adoption

A.F Blakemore expanded RELEX Solutions' tech for unified retail planning

Strategic Value: Competitor tech implementations reveal efficiency benchmarks. If rivals adopt new planning systems, expect improved inventory turnover—pressure-test your own systems to maintain parity.

flowchart TB

A[Competitor Websites] --> B

C[Social Media] --> B

D[Regulatory Filings] --> B[AI Monitoring System]

B --> E[Real-Time Alerts]

E --> F[Supply Chain Adjustments]

AI-Powered Predictive Analytics for Supply Chain Optimization

Predictive analytics transforms historical data into future-ready strategies. By modeling countless variables—from seasonal demand cycles to geopolitical risks—AI generates probabilistic scenarios that help mitigate disruptions before they occur. Companies using predictive supply chain analytics achieve 30% faster response times to market changes according to McKinsey.

Implementation checklist:

✅ Data integration framework:

- ERP system outputs

- IoT sensor streams

- Market sentiment indicators

✅ Model selection criteria:

- Time-series forecasting for demand patterns

- Random forests for risk probability

- Neural networks for complex variable interactions

✅ Scenario planning protocols:

| Risk Type | AI Simulation Focus | Contingency Example |

|---|---|---|

| Natural Disaster | Regional disruption impact | Pre-positioned safety stock |

| Supplier Failure | Alternative sourcing paths | Pre-vetted backup vendors |

| Demand Surge | Capacity utilization | Flexible labor contracts |

Ethical Considerations and Challenges in AI-Driven Analysis

While AI delivers powerful insights, responsible implementation requires ethical guardrails. Competitor intelligence must balance aggressive market positioning with legal compliance and corporate integrity. The most common pitfalls involve data sourcing ambiguities and algorithmic biases that distort strategic conclusions.

Ethical Implementation Framework

🔒 Data Privacy Compliance:

- Anonymize competitor data per GDPR/CCPA

- Establish clear boundaries between public intel and proprietary information

⚖️ Algorithmic Accountability:

- Document AI decision trails for audits

- Cross-validate findings with human analysts

🛡️ Bias Mitigation:

- Train models on diverse data sources

- Regularly test for demographic/geographic skew

🚩 Red Flag: Avoid any data collection method that requires bypassing security protocols—the legal risks outweigh intelligence benefits

Future Trends and Strategic Implementation

The next frontier in AI-driven supply chain analysis combines predictive intelligence with autonomous response systems. Expect three key developments by 2026: self-adjusting inventory algorithms that respond to competitor moves in real-time, blockchain-verified supplier networks that expose rival vulnerabilities, and cross-industry simulation platforms that model domino-effect disruptions.

Roadmap for AI Integration:

- Start with focused pilots: Target one high-impact area (e.g., raw material forecasting)

- Build cross-functional teams: Combine supply chain experts with data scientists

- Establish feedback loops: Continuously refine models with new competitor data

- Develop escalation protocols: Define decision rights for AI-generated recommendations

- Measure competitive responsiveness: Track time-to-adapt against industry benchmarks

flowchart LR

A[Current State] -->|AI Implementation| B[Future State]

B --> C[Automated Competitor Response]

B --> D[Predictive Risk Mitigation]

B --> E[Real-time Market Adaptation]

Conclusion

AI-driven competitor supply chain analysis has evolved from tactical advantage to strategic necessity. Leaders who systematically integrate these practices gain unprecedented abilities to anticipate disruptions, optimize operations, and neutralize competitive threats. The journey begins with focused monitoring of rival activities—where early detection of product shifts, partnership changes, or logistics innovations creates decisive market opportunities.

Transform your competitive intelligence today:

👉 Try RivalSense Free

Get your first automated competitor report and uncover hidden supply chain opportunities within hours—no credit card required.

📚 Read more

👉 How Competitor Success Can Fuel Your Strategic Upgrades: RivalSense's AML Transformation

👉 Competitor Intelligence Mastery: A Practical Checklist for B2B Leaders

👉 How Pasažieru Vilciens Outmaneuvers Competitors: A Blueprint for Strategic Dominance

👉 Mastering Financial Competitive Intelligence: Tracking Rivals' Funding, Profits, and Ownership Moves

👉 Decoding Competitor Moves: How Aeschbach's Strategic Product Shift Impacts Your Market Position